| Contact Us For Quotation | Email: 464560351@qq.com | Whatsapp&Wechat:+8618620373879 |

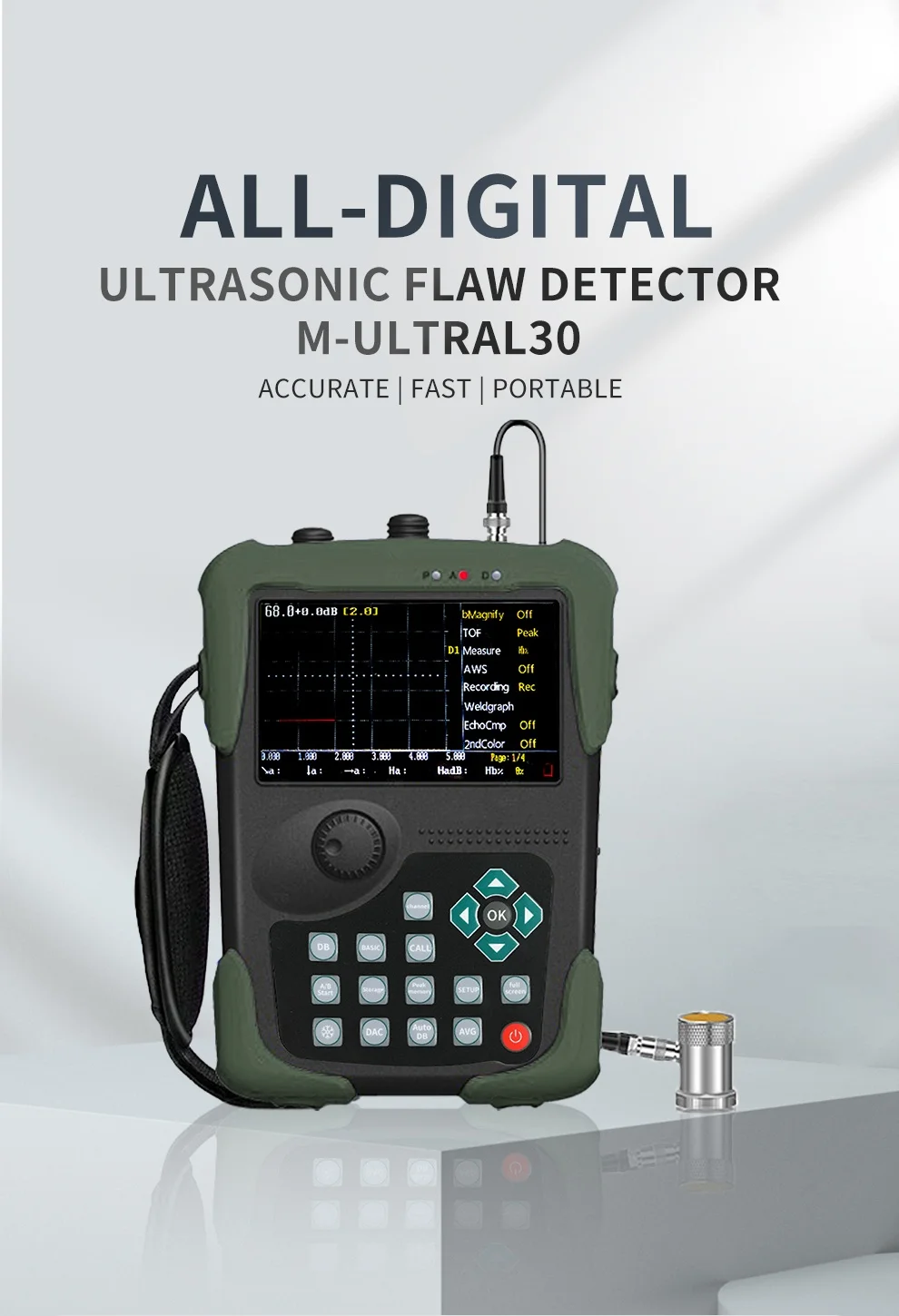

MINI-30E Mini Flaw Detector

Specifications

| High-precision professional version ((weld, plate thickness, thin parts, copper, aluminum and other metal crack detection, bonded parts, welded joints and other shaped workpiece crack detection thickness measurement) |

Parameters

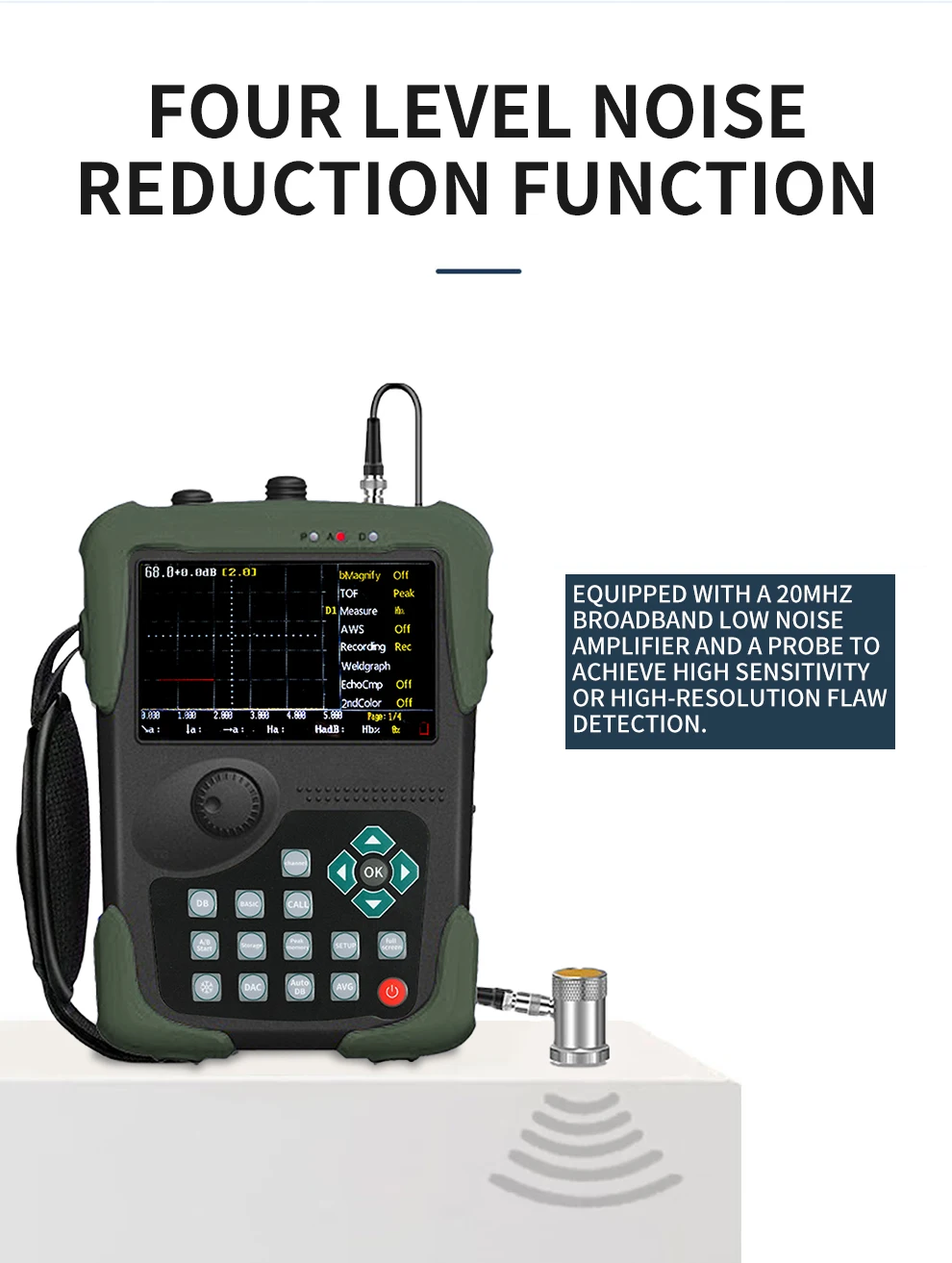

Detection range: 0-25000mm (steel longitudinal wave) Speed of sound: 1000-25000 Detection sensitivity ≥ 66db Dynamic range ≥ 50db Horizontal linearity error ≤ 0.1% Vertical linearity error ≤ 2% Remote resolution ≥ 32db Language: Chinese, English, and Russian Ingress protection: IP54 Noise suppression: up to 60% suppression Memory: 8G B/expandable up to 64GB Emission pulse: 400V Tip Pulse Noise Reduction: 4-stage noise reduction Weight: 1KG American Welding Society Standard aws: Yes Waveform Comparison: Yes Customized Acceptance |

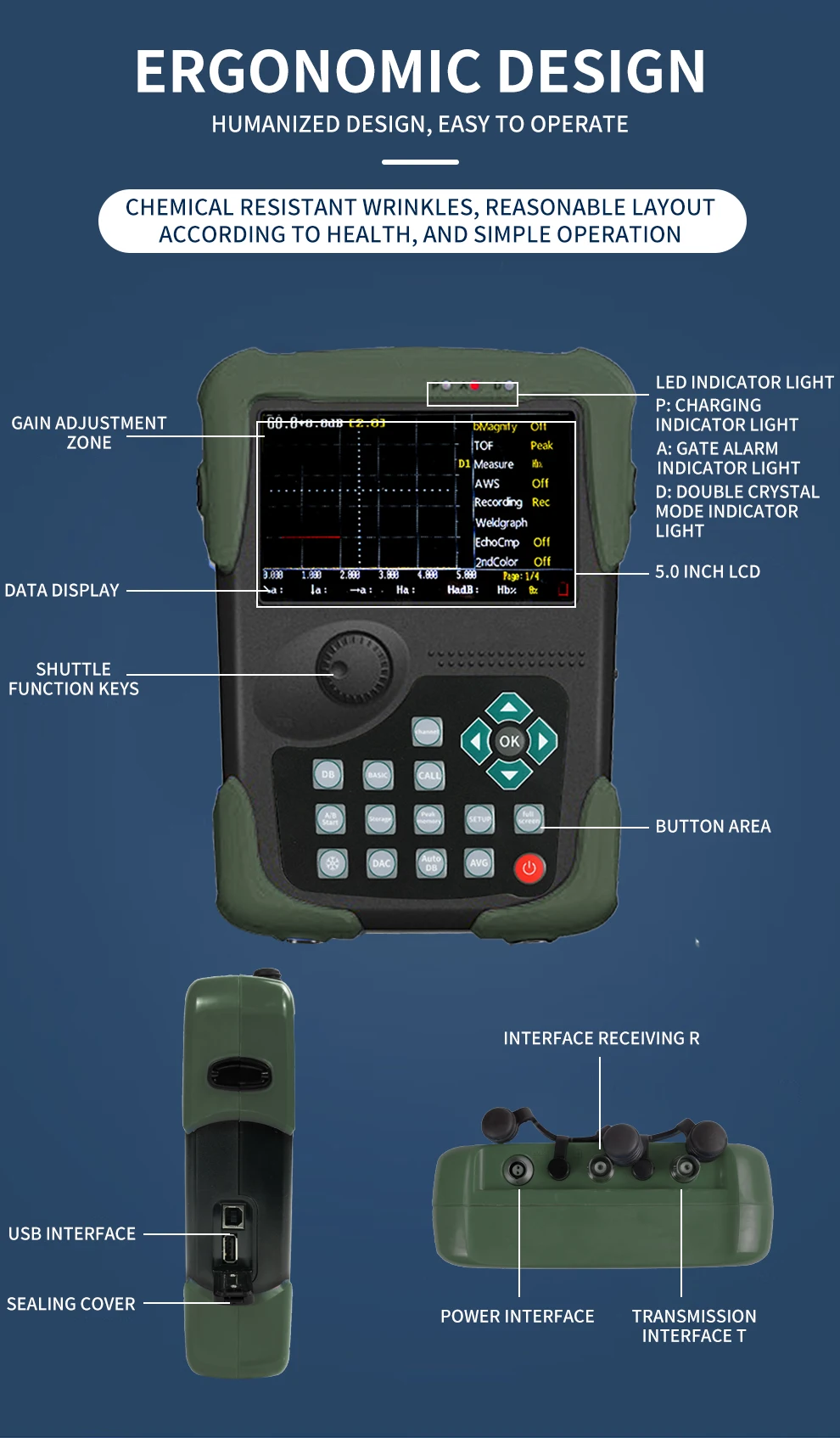

1. Waterproof grade IP54, waterproof, dustproof, drop-proof. Instruments on the market are generally not waterproof and moisture-proof, dust-proof, drop-proof. In the south, or the north of some humid environment, the instrument for a long time in the humidity, dust and other environments, will lead to circuitry and chips, components to accelerate aging, failure rate is very high! 2. All the chips of the instrument are 100% imported high-performance chips to ensure better accuracy and sensitivity, more stable performance, and less noise. 3. The weight of the whole machine 1kg (including batteries), instrument humanized design, flaw detection function keys can be left-handed a thumb to grasp all and set. 4. Containing the American Welding Society aws standard, and the domestic weld national standard. Performance and internationalization. 5. The secondary wave color is automatically differentiated to solve the problem of misjudging the location of defects. 6. Hardware sampling rate of 400MHZ, to ensure that the sampling data is true and reliable. 7. The gate automatically seeks for defective wave function, which improves the detection efficiency by several times. 8. Standard 8G memory, built-in 2 usb interface, easy to quickly read the data, the market instruments are basically only through the cumbersome preservation, and through the data line connected to the computer, and then through the software on the computer in order to read out the data, in terms of exporting data, the efficiency of hundreds of times. 9. Forging, casting and other parent material flaw detection, can break through the market instruments can only be made on the test block more than 100mm avg curve. That is to say, when detecting very thin workpieces, avg curves can be made, and during flaw detection, the size of defects can be read out directly from very thin workpieces. 10. Noise suppression, noise reduction and other functions, can be in the detection of some extreme workpiece, hidden interference wave, so that the defect wave easier to be captured. 11. The instrument uses Mitsubishi imported industrial TFT color LCD screen (screen clarity can be played directly on the movie), the market screen is basically a simple monochrome screen. 12. The keys are waterproof gold finger design, life expectancy of more than 10 years. Remarks: 1. Range, speed of sound, flaw detection sensitivity margin, dynamic range, horizontal linearity error, vertical linearity error, far-field resolution is mainly measured ability, accuracy, storage can support the probe range. 2. Clutter suppression, noise reduction, secondary wave color for small defects, special defects have better recognition. |

English

English